Tube Filling Machines

Tube packaging is a popular and versatile packaging solution, used in a wide range of industries, from cosmetics to pharmaceuticals. A reliable and efficient tube filling machine is an essential component of any successful production line, as it ensures accuracy and consistency of product filling, while also streamlining the overall process. In this article, we will explore the benefits of investing in a top-quality tube filling machine, and the factors to consider when making your purchase

Understanding Tube Filling Machines

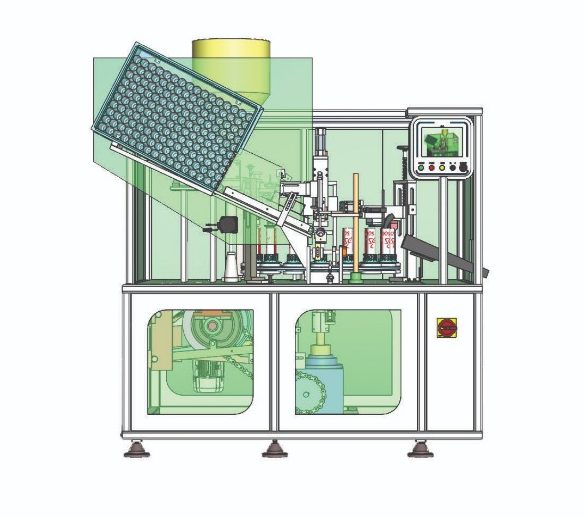

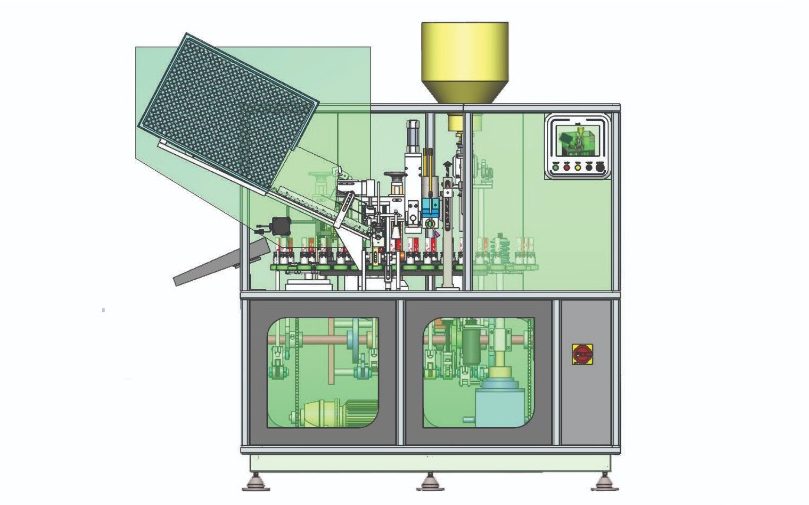

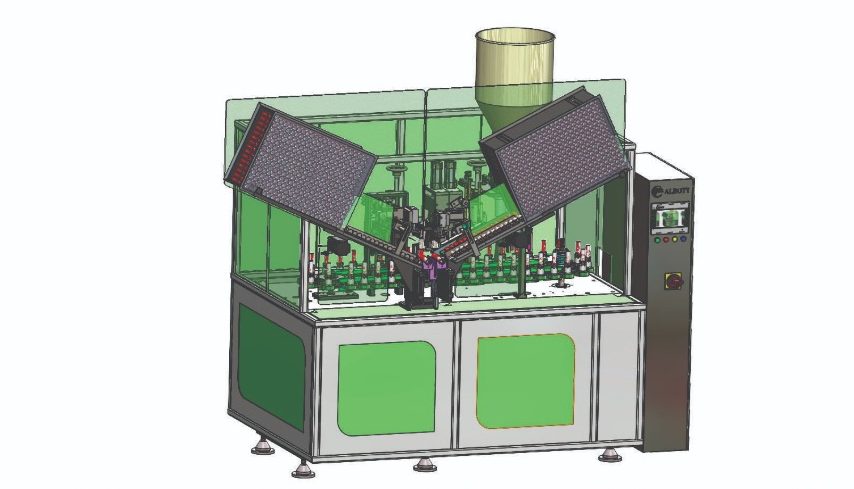

automatic tube filling machine

Tube filling machines are designed to fill tubes with a range of products, from creams and gels to pastes and liquids. They come in a range of sizes and configurations, from manual tabletop machines to fully automated lines. When choosing a tube filling machine, it is important to consider the specific requirements of your production line, including the size of the tubes you need to fill, the type of product you are filling, and your overall production volume

The Benefits of Investing in a Tube Filling Machines

There are numerous benefits to be gained from investing in a reliable and efficient tube filling machines, including:

Increased Accuracy: A high-quality tube filling machine ensures that your tubes are filled to the correct level, every time. This reduces waste, and helps to maintain the quality and consistency of your products.

Improved Productivity: By automating the tube filling process, you can greatly increase the speed and efficiency of your production line. This leads to higher productivity, and can help you to meet tight deadlines.

Enhanced Product Quality: A top-quality tube filling machine helps to maintain the quality of your products, by ensuring that they are filled to the correct level and with the right consistency. This helps to maintain the integrity of your brand, and can increase customer satisfaction.

Cost Savings: Investing in a tube filling machine can also help to reduce costs in the long-term. By automating the tube filling process, you can reduce the need for manual labor, and minimize waste.

Factors to Consider When Purchasing a Tube Filling Machine

When choosing a tube filling machine, there are a number of key factors to consider, including:

Capacity: Consider the maximum capacity of the machine, as well as the size of the tubes you need to fill. Make sure that the machine you choose is capable of handling your production volume.

Speed: Consider the speed of the machine, and whether it is capable of meeting your production requirements.

Product Compatibility: Make sure that the machine you choose is compatible with the type of product you are filling, including the consistency and viscosity.

Maintenance and Service: Consider the availability of maintenance and repair services, and make sure that the machine you choose is easy to maintain and repair.

Price: Finally, consider the price of the machine, and make sure that it is within your budget.

When choosing a tube filling machine, it is important to consider its features and capabilities. Some of the key features of a high-quality tube filling machine include:

Accurate Filling: The primary function of a tube filling machine is to accurately fill tubes with a specific product. A high-quality machine will have precise filling capabilities, ensuring that each tube is filled with the correct amount of product.

Efficient Operation: A good tube filling machine will be able to fill and seal tubes quickly and efficiently, reducing the overall time and cost of the packaging process.

Versatility: A high-quality tube filling machine should be versatile, allowing it to be used with a range of different tube sizes and products.

Easy Maintenance: A good tube filling machine should be easy to maintain, with simple and straightforward maintenance procedures. This will ensure that the machine is always in good working order, and minimize downtime.